Table of Contents

FID Online - Total Tar Analyzer 300

The IFK FID online tar measurement device TTA 300 was originally developed in the 1990s and has been further developed with the final goal for commercialization in the past years. This page only shows a brief summary of the measurement method. Further information can be found in respective publications.

Measurement Method

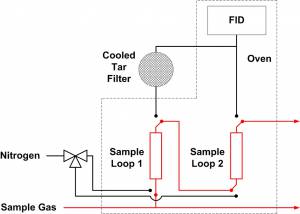

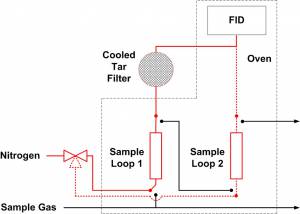

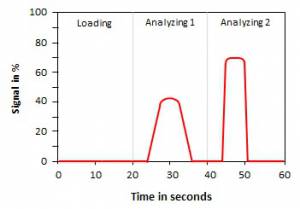

The measurement method is based on a difference measurement between two volumes of sample gas. The total hydrocarbon content of one volume is measured with an FID. The sample gas from the second volume is led over a suitable filter that captures the “condensable hydrocarbons” (tars). The remaining gaseous hydrocarbons (C1-C6) are subsequently measured with the FID. The difference of the total hydrocarbon content and the C1-C6 hydrocarbons determine the tar content of the gas.

Calibration

Calibration is done with propane in a concentration of the expected total hydrocarbon concentration of the sample gas. Propane is used as calibration gas for a gas mix because its response factors to common PAKs is around 1. The device has 3 measurement ranges up to a total hydrocarbon concentration of 120 gC/m³stp.

Filter Material

Based on the tar definition, filter materials for the tar condensation can be selected. According to experiences and tests at IFK, a mix of cellulose acetate (conventional cigarette filter) and a phyllosilicate called “bentonite” is used in the analyses of tars in producer gases of biomass gasification processes.

Photos

Bibliography

- Gredinger, A., Schweitzer, D., Dieter, H., Scheffknecht, G.: A Measurement Device for Online Monitoring of Total Tar in Gasification Systems. J. Energy Resour. Technol 138 (2016)

DOI: 10.1115/1.4032730

- Gredinger A., Spörl R., Scheffknecht G.: Comparison measurements of tar content in gasification systems between an online method and the tar protocol. Biomass and Bioenergy, 111 (2018) pp 301-307

DOI: 10.1016/J.BIOMBIOE.2017.01.026

- Neubauer, Y., Gredinger, A., Borgmeyer, J., Kleinhappl, M., Biollaz, S. M. A.: Comparison of two on-line tar-monitoring devices with off-line liquid sample tar-analysis operated on a test gas generation system applying ethene pyrolysis. Biomass and Bioenergy, 117, 2018, (63-70)

DOI: 10.1016/j.biombioe.2018.07.009